Senior Design is the capstone of Penn’s practice-integrated mechanical engineering curriculum. The two-semester senior design sequence challenges students to bring theory, skills, general knowledge, and inventive energy to bear on substantial engineering problems. There is no “typical” project and the variety is always surprising: some projects lead to marketable products; some explore a theoretical principle; some are just for fun. But taken together, they reflect the breadth and diversity of mechanical engineering.

Teams compete for four awards: Judges’ Choice, William K. Gemmill Memorial Prize, Francis G. Tatnall Prize, and the John Couloucoundis Prize.

Team ShatterSweep, comprised of Ling Xu and Ming Zou, were winners of the Judges’ Choice Award for excellence based on the discretion of the judges.

North Philadelphia neighborhoods are plagued with illegal dumping issues, and efforts to clean up trash on the sidewalks pose safety hazards to workers due to the presence of sharp objects. This sharp object sweeper aims to sweep up small sharp pieces such as glass in North Philadelphia residential communities in partnership with North10 Philadelphia, a community service organization.

Currently, the North10 team managing waste piling on North Philadelphia streets consists of four workers who manually pick up and dispose of trash with minimal protective gear. The sharp object sweeper reduces physical exertion as well as contact with sharp objects to increase speed and safety of sharp waste collection and disposal. The final form is a sweeper integrated with a custom glass-breaking system similar to the size of a small lawnmower. Workers can push this sweeper to effectively collect sharp waste of varying sizes, remove the container in the back to dispose sharps safely, and fold up the sweeper to compactly store in their trucks to transport between sites.

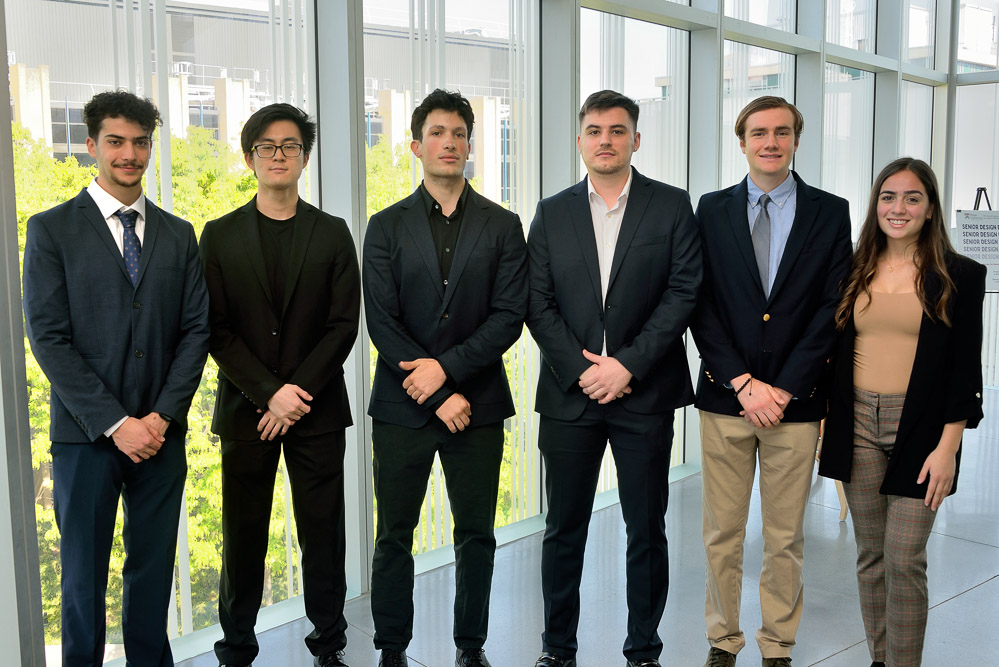

Team Spotter Pro, comprised of Teddy Constan, Alex LaBarca, Troy Hill, Krystian Kresso, Ahmed Laban, Eric Gao were winners of the William K. Gemmill Memorial Prize for outstanding creativity.

Spotter Pro revolutionizes weightlifting through an integrated system of fitness devices engineered to optimize performance, prevent injury, and provide comprehensive feedback. Combining a sensor-equipped barbell clamp and shoe inserts with a user-friendly mobile application, where the ecosystem of devices addresses the challenge of inaccessible and inefficient workout tracking, offering an unparalleled lifting experience.

Spotter Pro delivers real-time feedback on key metrics such as bar path, lifting velocity, and force distribution while offering automated repetition tracking to make recording workouts easier and more efficient. Users can refine their technique for specific exercises through Spotter Pro’s form suggestions and personalized workout plans, ensuring they get the most out of their workouts while simultaneously minimizing the risk of injury. Our system will cost less than two hundred dollars and will be small enough to fit into a standard gym bag. Additionally, a battery life of at most four hours along with a Bluetooth range of up to ten feet allow for efficient, carefree use.

Spotter Pro effectively bridges the gap between elite training programs and everyday gym-goers. Our system sets a new standard in weightlifting technology, offering enhanced performance and reduced injury risks for all stakeholders. Through rigorous engineering standards and collaborative efforts, our system promises to redefine strength training while holding affordability, safety, and efficiency paramount.

Team Crackle, comprised of Aditi Chintapalli, Runing Guan, Mei Han, Ilia Kheirkhah, and Shalika Neelaveni, were winners of the Francis G. Tatnall Prize for an outstanding project showing ingenuity, proficiency and usefulness.

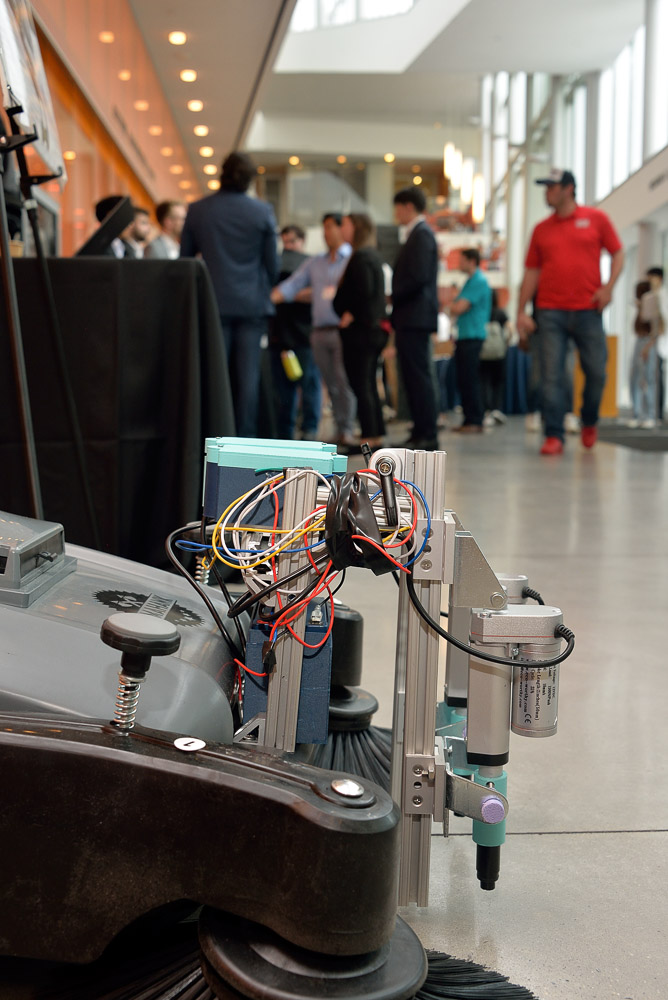

Airport runways are subject to deterioration, resulting in cracks caused by fatigue and environmental factors. This necessitates frequent and efficient maintenance, given that unrepaired cracks steadily expand, undermining the structural integrity of runways and significantly escalating repair costs over time. Currently, crack sealing is dominated by manual repair techniques. Manual methods are labor-intensive and result in operational disruptions due to prolonged runway closures. Additionally, manual crack sealing poses safety risks to the maintenance crew who are exposed to toxic sealant fumes.

Crackle provides a safer and more streamlined approach to runway maintenance, catering to airport administrations and maintenance contractors. Our solution integrates a sealant heating and deposition system with state of the art computer vision and sensing into a fully autonomous robot that is ready to deploy on any runway. In the context of the United States, where approximately $2 billion is spent annually on runway maintenance, Crackle is poised to deliver significant cost savings and enhanced operational efficiency, while ensuring worker safety by reducing their exposure to hazardous environments.

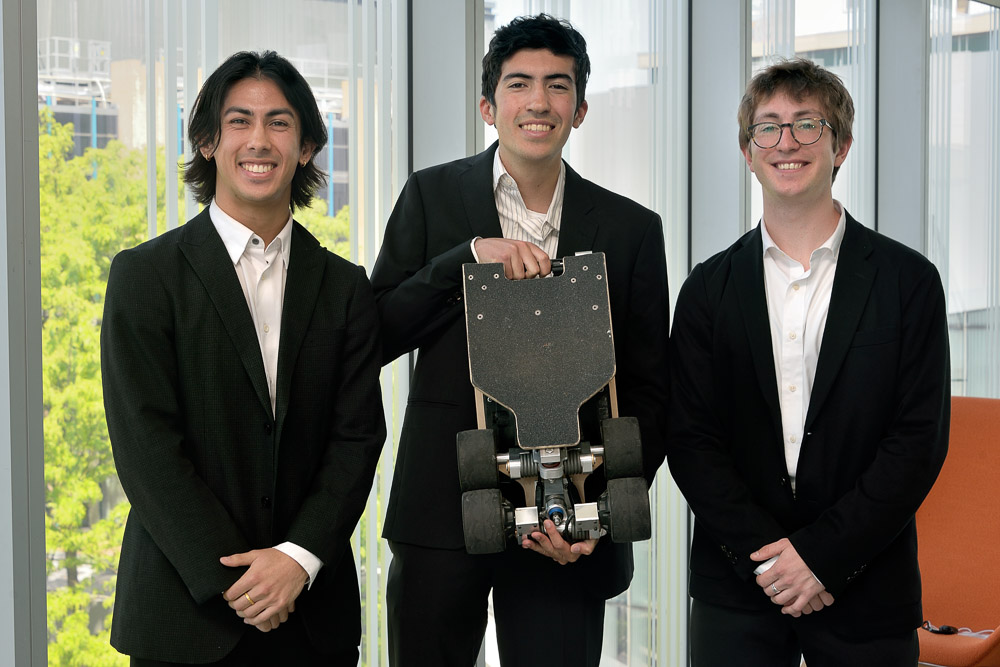

Team MorphBoard, comprised of Daniel Izmirian, Anton Ludwig, and Zachary Masotto were winners of the John Couloucoundis Prize for the best senior design presentation.

The global value of the micro-mobility industry is expected to double by 2030 to a total value of $440 billion. As this industry grows, there is increasing demand for a city-optimized personal transportation solution that combines the benefits of both stability and portability. Existing solutions fail to achieve a useful level of portability for the on-the-go travel required by college students and young professionals. Products in the market such as E-bikes and electric scooters are capable of traversing most obstacles encountered in urban commutes, but their inability to be easily stored between uses or to be transported easily by foot excludes a large segment of potential users. Morphboard provides a convenient solution with a small form factor that does not sacrifice the ride quality demanded by stakeholders.

Morphboard is a foldable, electric skateboard with an integrated suspension system to allow it to tackle obstacles encountered in cities such as trolley lines, curbs, or sidewalk cracks. Morphboard can be separated into three different subsystems: powertrain, suspension, and the deck. The powertrain is composed of in-hub motors capable of a 28 mph top speed and a battery pack with up to 11 miles of range. Morphboard uses an elegant torsion spring suspension integrated with a truck steering system to provide a compact shock reduction mechanism capable of smoothing out obstacles encountered during urban commutes. The board deck folds in half to reduce storage volume by nearly 50%, and allows for easy carrying with an integrated handle.

To learn more about all nine teams, click here.