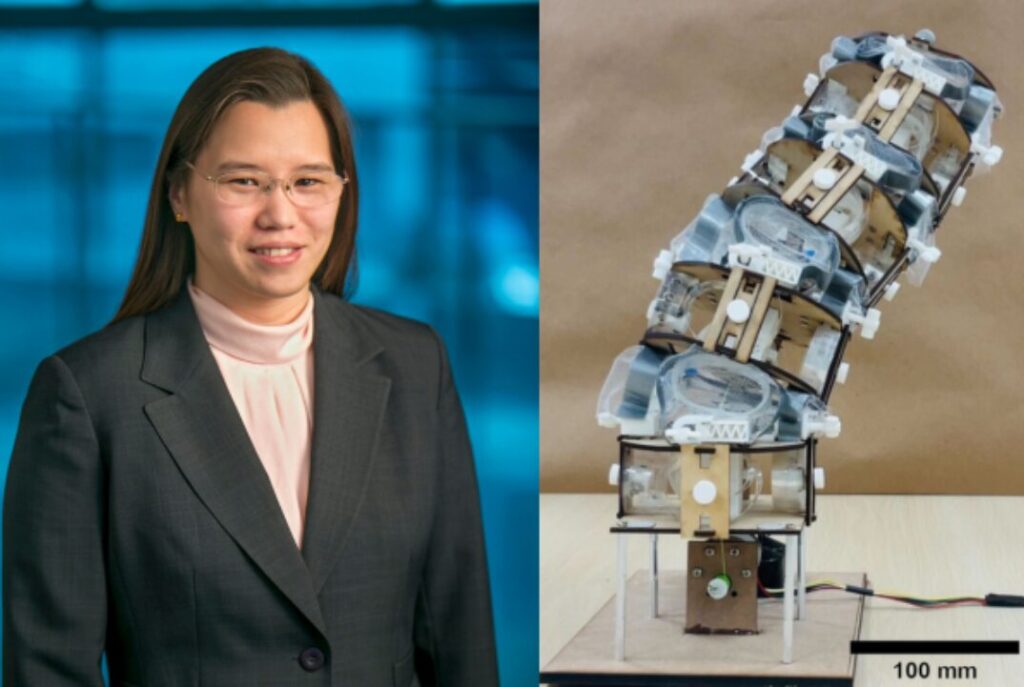

Inspired by the variety of muscles that control movement in animals, Cynthia Sung, Gabel Family Term Assistant Professor in Mechanical Engineering and Applied Mechanics (MEAM) at Penn Engineering, aims to advance movement and stiffness control in today’s robots to make future robotic platforms more adaptable and efficient. Her project, “Multiscale Actuation and Control for Tunable Stiffness Robots,” is funded by a three-year, $360K Early Career Program grant from the Army Research Office, a directorate of the U.S. Army Combat Capabilities Development Command Army Research Laboratory.

Animals utilize both small and large muscles to control their movement. For example, these local and global muscles work together fluidly to allow a mother monkey to swing from branch to branch while making fine-tuned adjustments to ensure her baby doesn’t lose its grip. Similarly, they allow a person to seamlessly transition from jogging on concrete to jogging on sand. This muscle integration is essential for all animals to navigate their surroundings. While we tend to credit the large muscle groups such as those in our legs that get us from place to place for our ability to move and adapt to our environment, the smaller muscles that allow us to change stiffness in our back to give non-verbal body cues or to balance on moving surfaces are just as important. It is these muscles that Sung pulls inspiration from as she designs new, integrated systems in soft robotics.

“Current robots don’t come close to matching the agility and maneuverability that we see in animals,” says Sung. “We think the reason for this is that animals have the ability to control not just joint positions, something current robots can do, but also their inherent mechanics—things such as stiffness, compliance, damping, friction and other physical properties. Recently, there have been advancements in new materials that allow us to change these sorts of properties, but we don’t know how to use them effectively in robots yet. This project will give us new insights into how we can combine new materials advancements with good robot design to create more capable and complex systems.”

The inspiration for this particular project? The human spine.

“The human spine has a combination of long global muscles down the back and small local muscles between individual vertebrae,” says Sung. “The global muscles help people to do large motions like bending or twisting, but the small muscles change stiffness, which helps with energy-efficient locomotion and allows us to make subtle changes in movement, balance and form.”

Using the spine as her model system, Sung is studying how hierarchical actuation—the different organizational levels of robotic movement—and control schemes can be used to enhance the capabilities of a soft robot over a wide variety of tasks. The work, informed by simplified mechanics models for soft robotics, will integrate computational approaches to modeling and distributed control of a flexible, compliant structure while taking into account the number of independent movements a given robot’s joints or parts can make.

This work has the potential to advance current soft robots’ abilities to perform quasi-static tasks, or those that only require gradual and slow movements without rapid changes in acceleration, to allow future soft robots to quickly and dynamically respond to rapid and sudden changes in their environments. These improvements will not only allow robots to move and react more like animals, but they will lead to new applications and solutions in the robotics field that can address a wider range of societal needs.

“I’m excited about the potential of this project to move us beyond existing robot design paradigms to being able to understand and leverage the interactions between robot behaviors, their body morphologies, and their actuation capabilities to create new robot designs,” says Sung. “I’m very grateful to the ARO Early Career Program, and especially to our program manager Dr. Dean Culver, for enabling us to explore this new direction in our work.”

This story was written by Melissa Pappas for Penn Engineering Today.