Two Ph.D. students in Mechanical Engineering and Applied Mechanics working with Robert Carpick, John Henry Towne Professor, have been recognized with scholarships from the Tribology and Lubrication Engineering Society (STLE). These awards recognize promising research that is driving next-generation lubrication technologies.

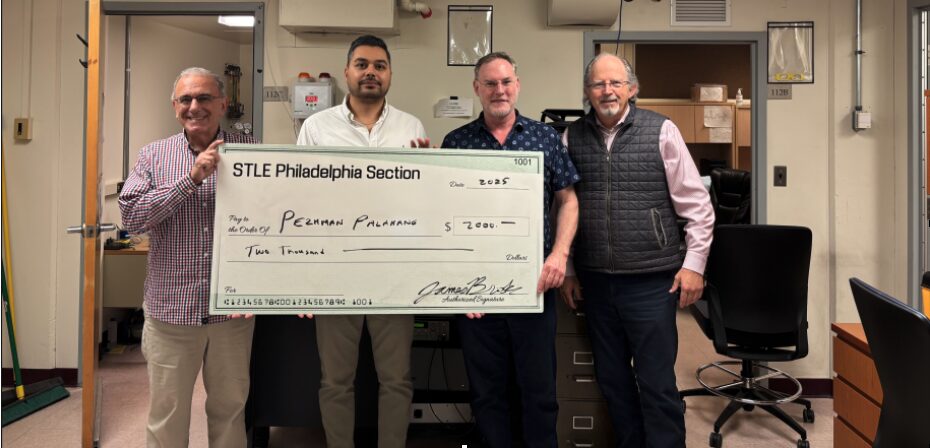

Pezhman Palahang: Pioneering In Situ BaTiO₃ Tribocoatings

Pezhman Palahang is unraveling the potential of in situ tribocoatings, which are ultra-thin films that form directly on working surfaces during operation. Supported by the U.S. Department of Energy and a leading nanoparticle manufacturer, Palahang’s work builds on the Carpick lab studies of ZrO₂ and TiO₂ nanocrystal sintering.

For the first time, Pezhman has shown that BaTiO₃ nanocrystals not only generate robust tribocoatings but also impart self-healing capabilities: when wear begins, the coating autonomously reforms in a BaTiO₃-rich lubricant. His systematic investigations reveal how load, speed, and lubricant composition control coating thickness, growth rate, and anti-wear performance. Notably, BaTiO₃ additives prevented scuffing failures in steel contacts, underscoring how surface roughness and nanocrystal chemistry combine to protect against extreme frictional wear.

Looking ahead, Pezhman will exploit BaTiO₃’s phase-transforming and piezoelectric properties under electric fields. He hypothesizes that electrically activated coatings could extend the life of EV drivetrains, wind-turbine bearings, and other high-demand components.

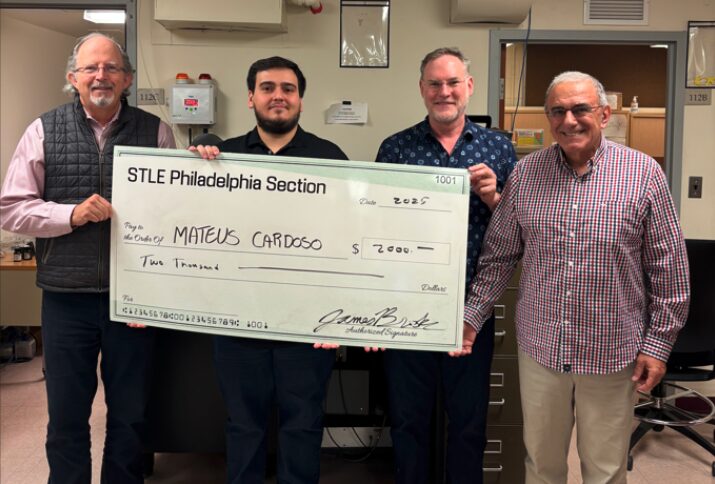

Mateus Cardoso: Decoding Grease Behavior with Zirconia Nanocrystals

Mateus Cardoso is developing breakthrough lubrication strategies by integrating zirconia nanocrystals into lithium complex grease. Cardoso crafted grease-specific testing protocols on a mini-traction machine to replicate the rolling and sliding contacts found in industrial bearings and gears.

His interdisciplinary approach, blending fluid rheology, multiscale tribological testing, and surface chemistry, aims to reveal the fundamental mechanisms of tribofilm formation and room-temperature tribosintering. Unlike conventional sintering, which demands temperatures above 1000 °C, tribosintering leverages frictional heating and pressure to bond nanoparticles at ambient conditions. These insights will inform the design of advanced nanogreases capable of protecting critical equipment, from wind-turbine gearboxes to aerospace actuators.

Cardoso’s collaborative network spans academic labs, government research centers, and private-sector partners—reflecting the team-based nature of modern tribology research. His early results are already guiding new formulations that balance lubricant viscosity, load capacity, and thermal stability.

Looking Forward

These scholarships not only celebrate Pezhman and Mateus’s achievements to date but also invest in the next phase of their work that could revolutionize how we think about lubrication and wear protection. As they move toward electric-field-tunable coatings and grease formulations optimized at the nanoscale, the STLE Philadelphia Section is honored to support research that will keep machines running longer, cleaner, and more efficiently.